Desert Race Ready KTM 450 SX-F

Story and Photos by Trevor Hunter

We’ve spent the last two years contesting the Best In The Desert championship aboard a KTM 450 and with success to boot. Back-to-back Open Pro class and Triple Crown championships, a couple of wins and several podiums make up the resume of our race bikes. And at the pro level, in order to be competitive, having a good bike underneath you that not only works well but also go the distance is critical. So what exactly went into building the championship winning bike for 2021? What are the maintenance intervals for this type of racing? What’s our top speed? We’ll cover all of that here! Click through to check out our 2019 Vegas To Reno Bike Build or our 2020 BITD Bike Build and see just how different yet similar these bikes are for the same intended purpose.

Our base platform for this year was a 2021 KTM 450 SX-F. While that may seem odd to race a motocross bike in long distance desert racing, it was the only bike available to purchase due to COVID and quite frankly, the differences between it and the XC-F is insignificant as we’d be changing all of the off-road specific changes that KTM made themselves. Also, John Kilmartin and Kilmartin Racing stepped up to help us this year and he supplied all of his other riders with SX-F models as well.

The first order of business is fuel tanks. IMS makes three different options for the new KTM four-strokes including a 2.6 Gal, 3.0 Gal, and 4.5 Gal tanks. Last year we ran a 3.0 Gal and had no issues, but the thought of running the bigger 4.5 Gal tank similar to what Skylar Howes had been doing intrigued us. We again started the year off on a 3.0 tank but right after the first race (Parker 250), we were able to get our hands on the big one. How drastic is the 4.5 Gal tank vs the 3.0 Gal tank? It’s quite a bit different, though not necessarily in a bad way. It’s quite a bit wider as the fuel tank extends out past the radiator shrouds and it’s very heavy, but for our intended purpose with this bike, it actually acted as a benefit. Neither Hayden nor I are the heaviest riders, weighing in around 160lbs.

As a result, getting the KTM to settle and stay planted on the ground, especially at 100mph, is really tough. For myself, it’s even trickier due to my lack of height and only being able to move around on the bike so much. The tank helps keep the bike planted underneath us and hitting small chatter, square edges, or in-ground rocks isn’t a problem for us anymore. Additionally, we can comfortably race 110-120 miles without refueling allowing us to avoid stopping for gas at every pit, though that isn’t super important since we have to run through the pits at every race anyways. For us, the 4.5 Gal tank is a winner and something we used at most, though not all races this year.

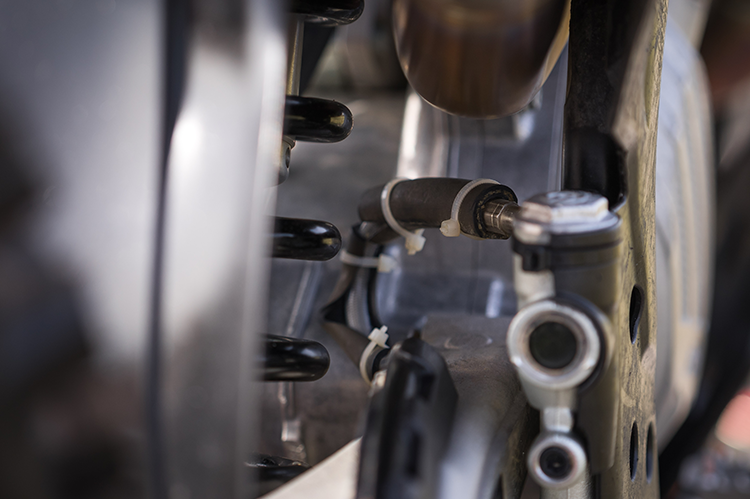

Next up is suspension. Like last year, we ran WP XACT Pro spring forks up front and paired it with a stock rear shock out back. Like the fuel tank, the added weight of the spring forks helps us greatly with front wheel traction and keeping the front end planted at speed. The Factory Connection valving is supple enough to soak up rocks and chop but still handle the occasional bigger G-Outs that we see on course. The rear shock has some custom valving using a KYB piston and KYB style valve stack. We’ve been tuning this for over a year now and have really come to like it for both desert and Moto/GP racing.

It’s on the stiffer side as it was originally developed for grand prix racing, but it offers a lot of “safety” in it as you can take bigger hits without any repercussions like you might with a softer, more typical desert shock. Because it’s stiffer, it suffers a little bit in the small chatter, but it was a trade-off and we decided it was best to go stiffer to be safe. The other important piece to this puzzle is the Pro Circuit Linkage System we ran. The shock’s valving and spring rate is designed to work specifically with this linkage rather than the stock system. In testing, we felt the PC linkage offered a more progressive curve being a little smoother initially but ramping up to handle bigger hits very well.

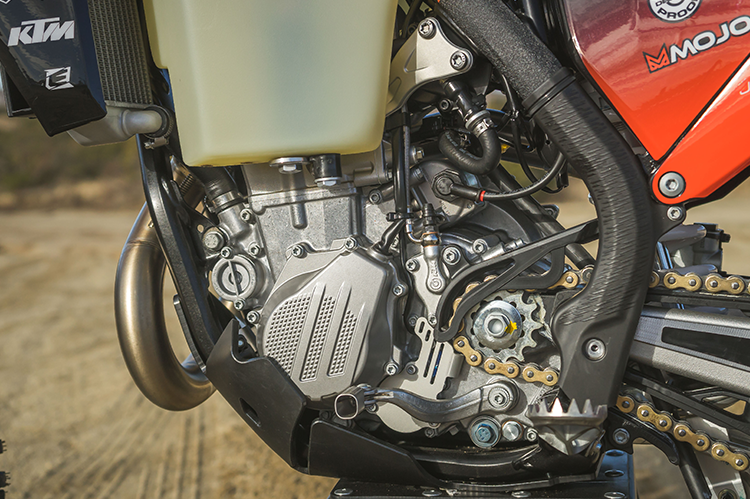

Motor wise, our bike is almost completely stock. We started the year with a Vortex ECU and really liked the power. It smoothed out the initial hit of the power yet pulled harder through the mid-top end which is perfect for what we are doing. Additionally, the smoother power characteristic also smoothed out the chassis feel as well, typical of what we find in most 450’s. However, when racing at high speeds in top gear for a significant amount of time, we had a couple instances where the bike would start bogging down and eventually die as if it had run out of gas. Each time, it’d start right back up and run fine again but it wasn’t confidence inspiring. We could’ve messed with the ECU more and tried tuning it, but we wanted to play it safe and stuck with the stock ECU from Vegas to Reno and on. Other than the ECU at the beginning of the year, our motor was stock internally for hop-up parts and mods. Blud Lubricants kept our motor running strong this year. The Scorpion Oil is very durable and lasts a long, long time. Even after V2R, it still looked good, not burnt or black.

For a transmission, we reverted back to an older 2019 XC-F transmission. In 2020, KTM changed vendors and Pankl now produces the tranny. However, there is no 6th gear available to fit the new splines of the Pankl transmission. We also could’ve put a new XC-W/EXC transmission into this new bike, but we had access to the ‘19 XC-F tranny so we stuck with that as the cheaper route. Either way, they would both work. The ‘19 XC-F tranny has the EXC 6th gear installed on it, and you can read about installing it and what parts are needed HERE. The overdrive-like 6th gear works wonders in the desert and is a big advantage of riding the KTM.

Gas is the only “performance mod” we did to our motor. We tested with F&L Racing Fuels last year and were able to get a few MPH out of this gas combination. We run a 50/50 blend of “Moto” and “SP3”. SP3 is an oxygenated, leaded fuel with an octane of 113 and Moto is an unleaded fuel with an octane of 95.5. The F&L combo helped the bike pull the taller gears with more pulling power and even gave us a couple extra MPH on top speed. The SP3 itself made the biggest difference, but we found mixing it 50/50 with the Moto fuel didn’t hinder performance and is quite a bit cheaper than straight SP3.

Pro Circuit helped us with a T-6 exhaust system. It’s a little heavier than their Ti options but it is stronger than the Ti models which is ideal for this type of discipline. One thing to note, and a common theme with endurance racing on all aspects of the bike, is the wear and tear the exhaust system took. Despite not having a crazy number of hours on it, we actually blew a hole in the exhaust at the Laughlin round. The exhaust only had around 40 hours on it, but since our races last anywhere from 3-8 hours and they are all very fast, the exhaust gets really hot and stays that way for the duration leading to premature wear. As a precautionary, we’ll likely try to replace the muffler halfway through the year before Vegas to Reno next year to be safe.

The suspension also takes a beating, and primarily in the shock. Racing at high speeds, the rear end is constantly squatted and putting a load on the shock while keeping the fork “unweighted”. Plus, hitting whoops and square edges drives into the shock more so than the forks. Working with our suspension tuners, rebuilding the shock every other race, if not every race is important. After a 1 hour test session prior to V2R, then racing V2R for 8 hours, the shock looked like it had been through a full 40 hours of use. The fork doesn’t see quite the abuse as the shock but can still use a rebuild likely every other race.

Kenda Tires and Nitromousse kept us hooking up out in the desert. Our go-to front tire was a Washougal II 90/100-21 front tire. For us two, it works well under heavy braking and gives us good front end traction through corners in all terrains. Overall, it is a very versatile tire that worked everywhere we took it. Also, we don’t notice much performance loss as the race miles accumulate. The only time we felt the front end lacked was in the final ~75 miles of Vegas to Reno this year, but it already had over 400 miles on it up to that point.

Out back, we primarily ran a Kenda Parker DT and you can’t go wrong with that tire. Like the Washougal II front, it is very versatile and works well in every situation from braking to accelerating and in sand to rocks. However, for the two long distance races (Silver State 300 & Vegas to Reno), we ran a Kenda K270 dual sport rear tire. This tire lasts forever, easily going the 250-300 miles we need it to go in those races. Also, on hard packed roads which make up a majority of the terrain in those two races, it hooks up very well under acceleration. Under braking, there isn’t a ton of traction and it likes to break loose, but we are able to adjust our riding to that and don’t feel it is too big of a hindrance.

Mousse’s are tricky for high speed, long distance races. The more they heat up, the quicker they wear out and sometimes even disintegrate. Nitromousse has arguably one of, if not the most durable mousse on the market at the moment and we’ve had pretty good success with them. For the shorter races like Parker, Laughlin, etc. we’ll run standard size mousse’s (220-21 & 305-18) in our tires and have no issues. For races like Silver State and V2R, we bump up a mousse size up front and run a 235-21. For the rear, we still run a 305-18 mousse in the K270, but since it is a smaller tire, it acts as an oversized mousse. If we were to run a Parker DT rear tire at these races, we’d run a 325-18 mousse. Are they really firm and stiff? Yes. Do they last? Absolutely. We’ll run the entire front mousse with ease and it still looks pretty good at the finish. In the rear, we switch wheels at around the halfway point of V2R (250 miles) and the mousse still looks as new. Silver State we go all 300 miles and again, there isn’t much wear and tear on the mousse. Also to note, we use quite a bit of Nitro Lube when mounting the tires to help keep them cool. We’ll use 2-2.5 tubes of the Nitro Lube per wheel and they are usually still lubed after the race. With tire soap, we’ve found soap dries out very quick at high speeds and don’t suggest using it.

GPR Stabilizer harnesses our front end when racing at Warp speed across the desert. Their newest split style Triple Clamp and V5 Stabilizer were new to us this year, and while it took some time to get used to, it got the job done. Stabilizers are a huge help in this racing discipline as it allows you to relax more and for when you hit a rock or bump at speed unexpectdly, it helps soften the blow. Fasst Co Flexx Handlebars added some needed comfort and the bars actually help absorb some of the smaller chop and hits, which in turn allows us to run the suspension slightly stiffer.

TM Designworks handled our Skid Plate and Slide-N-Guide needs. Their Extreme Skid Plate is pretty burly, extruding up and out to protect the cases and frame from rocks while also boasting an extended plastic piece to cover the underside of the linkage. Their Slide-N-Guide Kits are tough as nails and would probably outlast the bike itself both in terms of durability wear and in strength against impacts.

Bullet Proof Designs’ Rear Disc Guard is as good as any that we’ve tested. It’s a one-piece design which is always nice, it’s got some pretty good gouges in it while our rotor doesn’t, and we haven’t had any fitment issues with any of them in the past.

Dirt Tricks handled our sprocket needs while we ran DID O-Ring chains. The rear sprocket could last an entire year easily. The front sprocket and chain were changed for Vegas To Reno, more as a precautionary measure, though they still had life left in it. Like we said in the beginning, we’re racing for a championship and we don’t want to leave anything to chance. One of our downfalls this year is that we ran master links instead of rivet links on the chain. At V2R, we had a rear wheel installment issue during our pit and it led to the master link falling off, though we didn’t know until looking the bike over at the finish. Again, we lost another master link at the Cal City DC, again not knowing it until after the finish. Luckily it didn’t cause any trouble, but we’ll look to avoid that for 2022 with a rivet link. For gearing, we swapped between 14/48 and 15/48 depending on the race. SS300 and V2R saw a 15 go on the bike since they have a lot of high high speed sections that can last for miles at a time. Our top speed with Hayden on the bike was around 111MPH with the 15/48 gearing setup. With the 14/48 gearing, top speed is right around 100MPH.

Since we’d be on the bike for long periods of time, and a lot of sitting, we ran Seat Concepts’ “Comfort” seat. It’s very comfortable, as the name suggests, and keeps our bottoms from becoming fatigued and sore after a long day in the saddle. What might be best about the seat is how wide it is. It acts as another point of contact for the legs and helps with squeezing with the knees.

Dubya USA supplied the wheelset for the year in the form of A60 rims and Kite hubs. Even with the super strong A60s laced up, we put a few dents in the rims by year end, though they were nothing major.

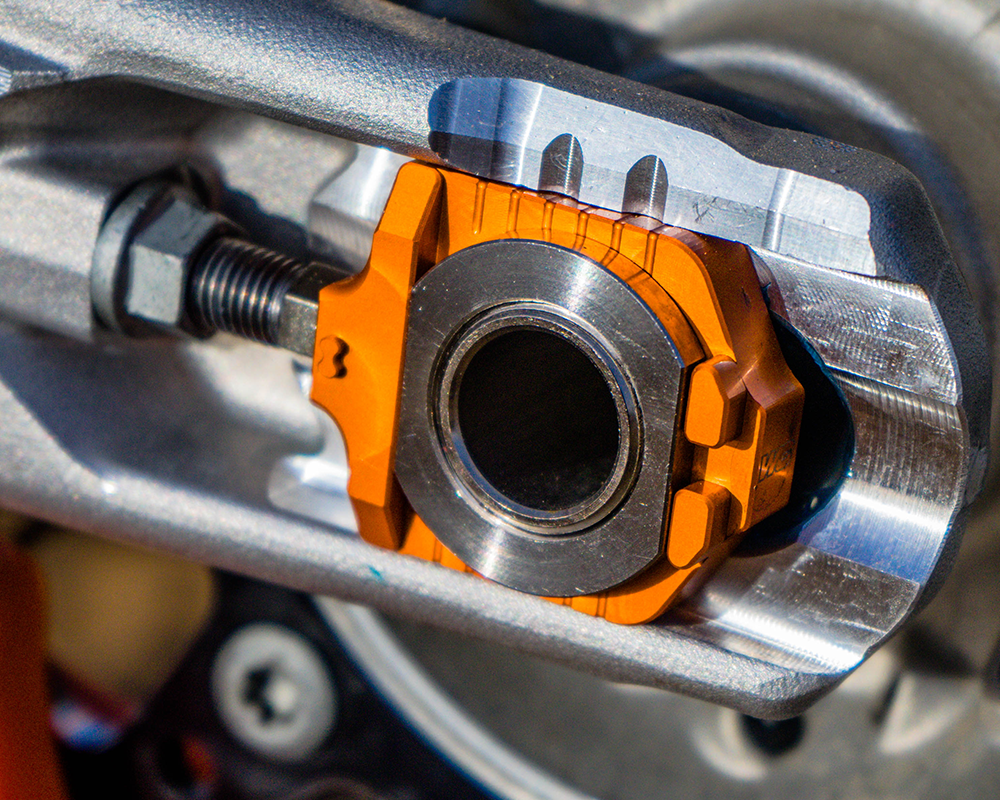

A couple small but significant things that aided in comfort are AME Grips and Works Connection Axle Blocks. The ½ waffle AME’s are soft enough to help preserve our hands without feeling too mushy. The WC Axle Blocks add a touch of comfort under acceleration and in small chop and help dial in the ride that extra 1%.

What kind of maintenance did we perform throughout the season? Not a whole lot. After Vegas to Reno, we changed the top end, though everything looked like new. The valves were in spec, the crank felt fine, and the piston could’ve easily gone on longer if needed. A set of throttle cables was replaced around the 40 hour mark to get that buttery smooth feel back. A couple sets of Brembo rear brake pads were used throughout the season while one set of fronts was all that was needed. A set of tires were used at every race, with V2R being the only one where two rears were needed and worn through. We also went through a few fuel pumps, luckily none during the race though. KTM fuel pumps seem to be the most finicky out of all of the EFI bikes and we experienced a couple bad ones. Part of this may be due to running race gas and it is something we are looking in to to see if that could be the detriment to our fuel pumps.

This bike won a championship and races, exactly what it was intended to do. Is it heavily modified with a factory motor and special hop-up parts? No becuase it really doesn’t need it. The saying goes “To finish first, you must first finish.” By keeping a relatively stock platform motor wise, we were able to avoid any costly break downs and DNFs throughout the year, despite not having the absolute fastest bike at all times. We feel we built the perfect blend of achieving speed without sacrificing reliability with this bike and it shows at the end of the year. After all, do we really want to be going that fast? No, but we do like to win races so yes…