AltRider Complete Crash Bar System

Company: AltRider

Price: $696.97

- Solid, frame mounted, cage to protect radiators,motor and DCT /clutch cases

- Offered in silver, black and red

- Made in the U.S.A.

- Attachment point for auxiliary lighting

- Air Filter changes require removal of upper bars

- Compatibility issues with aftermarket exhaust and skid plates

What it is

- AltRider’s Crash Bar system for the Honda Africa Twin

AltRider is a Seattle, Washington based company that offers a variety of Dual Sport Adventure bike specific products with a focus on bike protection. We tested AltRider’s complete crash bar system on a new 2017 Honda Africa Twin DCT. The crash bars are essentially an exoskeleton "roll cage" designed to protect the pricey parts of a large adventure bike from the basic topple-over to a nasty crash. This is a system of stainless steel tubes which stylishly follows the contours of the high gloss painted plastics and tank down to the vulnerable areas of the bike which include the radiators, engine and clutch cases. The system is offered in silver, black or red finishes. The AltRider crash bar system is a three part series (also sold individually) consisting of 1” and 1 ¼“diameter 304 stainless steel tubing. The company incorporates a CNC design process, CNC mandrel bends, 3D CNC laser cutting and hand TIG welds resulting in a product that is claimed to be stronger through materials, fabrication and design.

This 100% American made product is focused on affixing the crash bars to the bike’s frame using pre-existing mounting points (no extra drilling or relocating parts). Connecting the frame and the bars is believed to mitigate impact through the disbursement of energy into the bar system first and then into the frame of the bike. With the crash bars distributing the force of impact, the engine and clutch remain relatively isolated by the process of encapsulation.

How it works

- An external roll cage protection system

- Easy to moderate install.

- Stainless steel tube construction

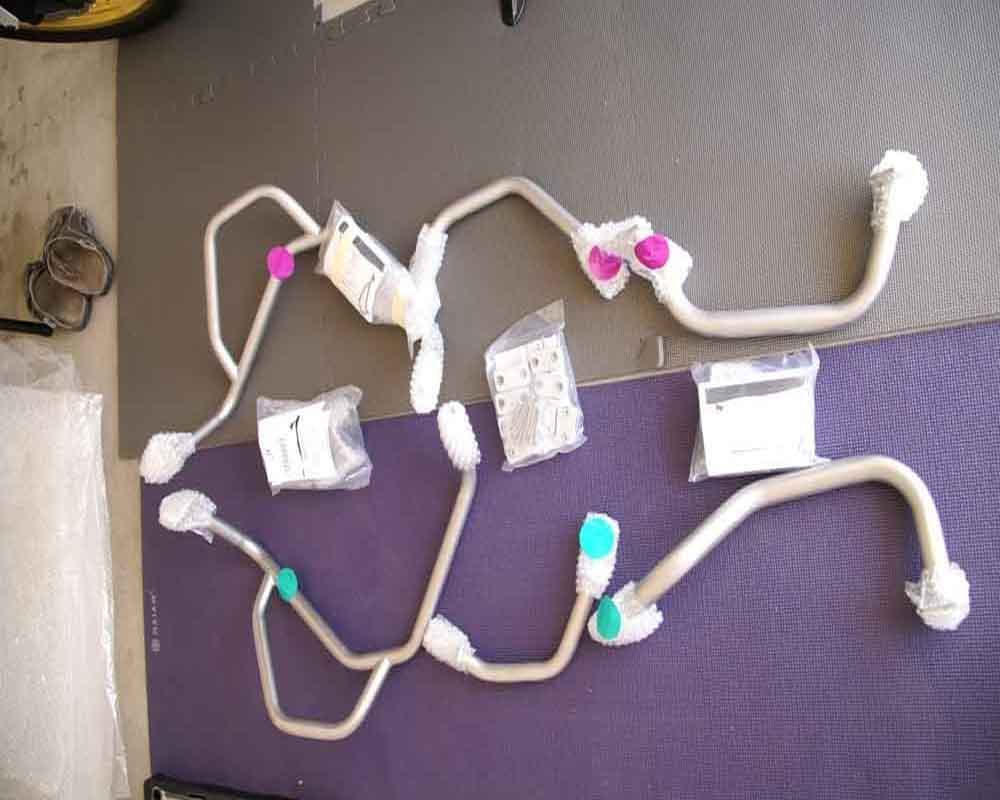

The crash bar system ships complete with the upper, lower, reinforcement bars and necessary hardware. Since unboxing has become a pivotal moment for the purchaser, let’s talk packaging. AltRider packages their product to overcome a nuclear event. All items arrive in a single box surrounded by packing paper and plastic sheets. The bars are completely wrapped in bubble tape with an extra bubble tape layer at each bar end. Instructions, hardware and thread lock are bagged and taped to one of the bars. All parts are grouped per install location and placed in a bubble bag. Laterality is indicated by a turquoise or magenta sticker affixed to each bar taking the guesswork out of which part fits what side. This method of packaging is well planned and keeps all hardware grouped for each part of the installation adding to the ease of install. After pulling the bubble tape from the product, it is recommended that the bars are cleaned of excess tape residue to avoid dirt build up and a speckled appearance after install.

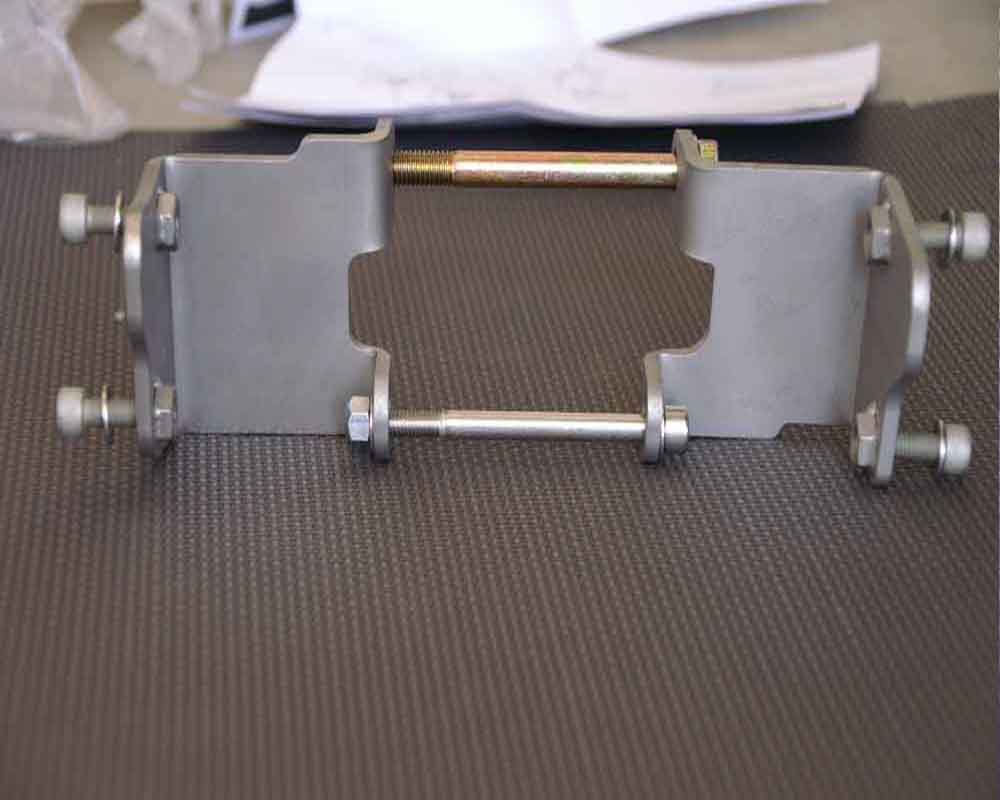

All provided steel tubing, brackets and attachment hardware were inspected for obvious structural defects especially near the bends and all appeared to be in excellent condition. All welds were also inspected for completeness, symmetry and free of misplaced material due to the welding process. The welds also appear to be in excellent order and free of obvious imperfections. Attachment brackets are laser cut and have smooth clean edges free of burrs, cracks or warping. When measured, the mounting bracket plates were thicker than advertised on the web page with the thickest measuring 6.57 mm. Despite the bulkiness and solid feeling of the tubing, the whole system weighs in at just over 21 pounds (9.5 Kg) including the mounting hardware.

The instructions sheets are part specific as the crash bars are also sold separately. A list of necessary tools are provided on the front page (exception of a torque wrench) and step specific photos and torque specifications follow. There are also tips for install in the directions which, if read, makes the install even easier. As with most photocopied instructions, the photos become a little washed out but AltRider has the install instructions and photos duplicated on their website and clarity is far greater. To further enhance the ease of install several videos are available which cover some or all aspects of this install.

When choosing the complete set or individual upper or lower protection the bracket set is the first part of the install. Installing the Bracket set is straightforward requiring the removal and replacement of the M10 screws and nuts that retain the motor mount. Following the instructional tips will save you much frustration as alignment of the motor mount brackets and washers may shift adding to frustrations. The mounting bracket forms a solid cradle around the exhaust on either side of the frame and becomes the attachment point for both the upper and lower crash bars. Once installed, it is recommended that the bolts are left hand tight until the other aspects of the install are complete.

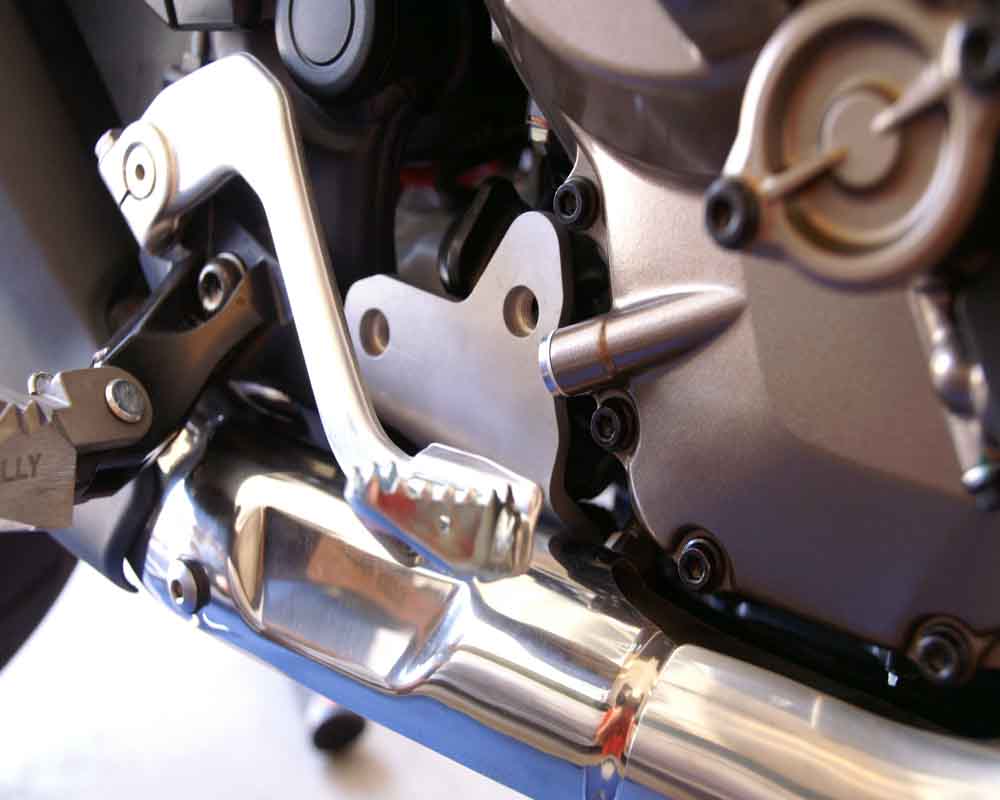

With the bracket set in place, the task of adding the upper bars is a matter of placing the under nose bracket and adding each side of the upper crash bar. The nose bracket is a bit difficult with one set of hands but feasible. The nose bracket attaches to the bike via the front fairing bracket plate using two M6 button head screws. To AltRiders credit, the bracket features a third attachment point inboard of the two outer points giving the system added rigidity and prohibiting vertical movement. The right and left upper crash bars simply attach to the bracket set inferiorly and the nose bracket superiorly. The mounting brackets were left only hand tight allowing for some flexibility and manipulation as were the upper crash bars. Once all parts were installed, the task of tightening to torque specifications was simple.

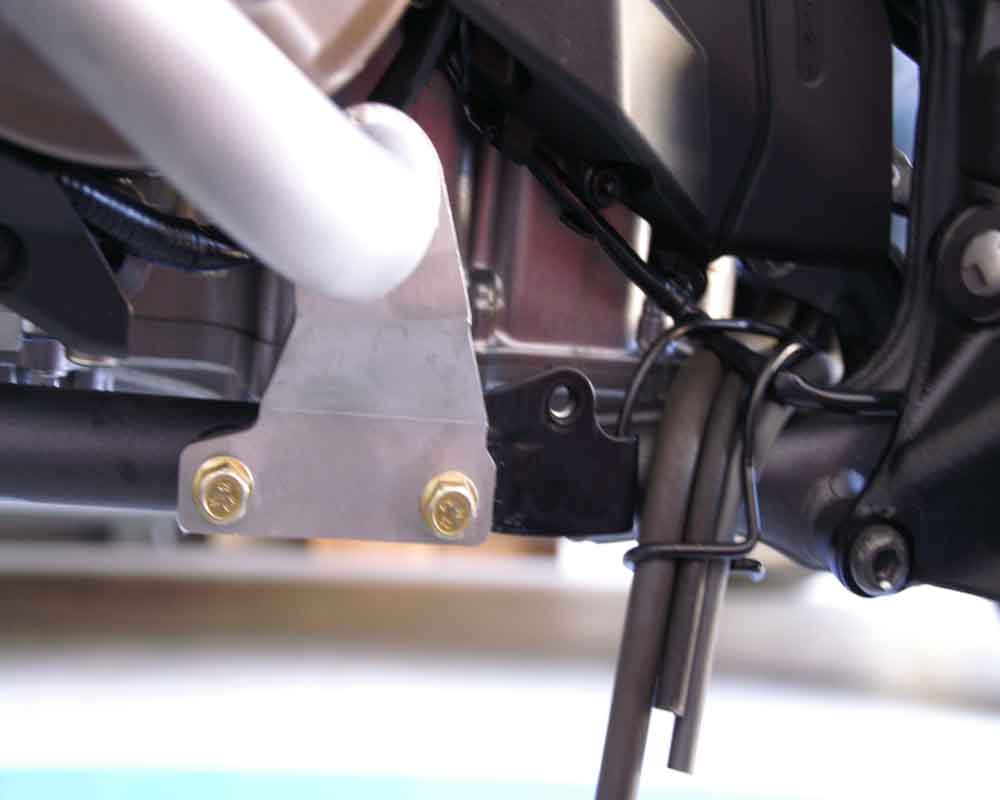

The next install is the lower crash bars and right side supporting bracket. This mounting process incorporates a well planned set of mounting points that avoid attachment to engine cases. All mounting is directly affixed to the frame of the bike with thru-hole brackets, not slip-fitted brackets. Mounting the lower bar on the right side requires a temporary relocation of the exhaust and the unfastening of the exhaust sensor. A mounting bracket is added just behind the clutch case and attached to the frame with provided bolts. This does provide limitations as the inboard mounting on the exhaust side may conflict with certain aftermarket exhaust systems and skid plates. Once in place, the crash bar on the right protects the clutch case and prevents the brake lever from puncturing the case as the crash bar lies directly between the two.For the left side, the crash bar is easily mounted to the frame with the removal of the skid plate and two bolts supporting the vent tube routing bracket.

The lower bars are stout at 1 ¼” and for good measure. The lower half of the bike will ultimately suffer the brunt of any topple over, crash or brush up on rocks stumps and trail debris. This larger diameter lower bar design is the result of AltRider's partnership with a BMW riding school in the Pacific Northwest. As you can imagine, the company’s R&D benefited by having their products abused by riding school participants. AltRider was able to improve the final product by understanding the drop characteristics and protection needs of different bikes with varying widths. The width of a BMW F800 GS closely resembles that of the Africa Twin and lessons learned from the carnage of loaner bikes was applied to the bar system for the Honda,

The final process is the addition of the tie bars. These bars are to tie the upper and lower bars together and add further protection toward the rear of the bike. They are added via a clam shell attachment and alignment takes a little experimentation to find the sweet spot where the inner surface of the clam shell meets evenly with the bars. These brackets do take a good amount of abuse as with each drop of the bike the brackets received the most gouging.

This test was completed over a period of several months and in various conditions because some riders may choose to use this bike as a sport tourer and others as a dual sport. To provide a complete evaluation ot these bars we started with a stock 2017 Honda Africa Twin.The bike was ridden in the stock configuration for the first 500 miles to obtain a baseline feeling for the handling, road noise and riding positions. From this baseline the crash bars were added and evaluated. In keeping with the dual personality of the Africa Twin, the crash bar system was tested in two configurations and under separate riding conditions. The first configuration was utilizing the stock skid plate and tires. All mileage in this configuration was performed on street and highway conditions at speeds varying from sub walking pace to 85 mph. There was no noticeable change in bike performance despite the added weight. Road noise remained the same as well as perceived airflow over and around the bike. There were no added vibrations, harmonics or whistling produced by the system. Riding position did not change and there was ample distance between the riders knees and the upper bars. Interference with riding boots up to size 12 never occurred despite the small stock foot pegs which force the riders foot inboard. The bike was ridden for close to 700 miles in this configuration awaiting the install of new items for off road use. Prior to the install of new parts, all bolts were rechecked for torque tolerances with not a one out of spec. Gap measurements were also taken near crucial engine and body components to gauge compression of the bars following the anticipation of off-road mishaps.

The addition of 50/50 road/dirt tires, Barkbusters, IMS Rally footpegs, AltRider rear rack, AltRider skid plate and SW-Motech centerstand were installed for the off-road (Dual Sport) conversion. The bike was again tested in similar fashion adding off-road mileage. The crash bar system did not generate noticeable changes from the stock configuration. Road and engine noise did, however, increase due to the knobby tires. A slight increase in the exhaust note deflected up from the massive AltRider skid plate making it difficult to gauge any new onset issues with the bars. The addition of new protection deemed it necessary to take this eager bike into the dirt and inevitably a test of the crash bars. Following two rallies and many hours on dirt, street and highway, the bike and riders tested the durability of this crash bar system. In all cases to date, the crash or topple over were all at slower speeds sub 30 MPH or a stationary drop due to a misplaced foot on gravel (insert buddies laughter here). Although the true test of crash bars would be to subject the bike to a T-Bone with a truck, we did not include this scenario into testing due to a lack of willing participants. .

After a total of 6000 miles, the bike was brought back to the garage and bolts were tested to torque specs with no variations. The gap clearances between the cases and the bars did not change to a noticeable degree. The bars were not compromised with the exceptions of some scratches that are easily buffed out and a few stubborn gouges on the clam shell brackets on the lower bar attachment point. Due to dusty conditions when riding, the air filters were changed and the removal of the faring shrouds did require the removal of the upper bars. In contrast, the design of the full system does also allows the removal of the clutch filter without issues making routine maintenance unencumbered. The access to the battery compartment and battery removal is also unencumbered.

The Africa Twin is a narrow motorcycle and in its stock configuration, without crash bars, the engine or DCT cases as well as the fuel tank appear to be most vulnerable. A simple topple over on a flat surface let alone a tight rock lined trail could result in a very expensive repair and time not in the saddle. This being said, these bars are not just for the off road enthusiast as topple overs to crashes do occur for those using the bike as a tourer. Both on and off road riders will also appreciate the ability to add auxiliary lighting protected by caged mounting points. Unlike the iconic BMW boxer engine, the parallel twin keeps the lower portion of the bike narrow as well. When the bike does hit the ground the tendency is to rest completely horizontal. Having a set of crash bars offsets this resting position by standing the side of the bike off the ground and slightly elevated from horizontal. This position allows the rider to get under the bike and safely lift the 560 pound stead by rocking it on the crash bars (not a case) and into an upright position. We also needed to slide the bike into a better location and the crash bars enabled unrestricted movement to a more ideal location without damage to the protruding DCT case.

Where the AltRider system shines is in the company’s commitment to the customer on the road, trail or both. This is a company formed and built by accomplished riders such as it's owner Jeremy LeBrenton. The attention to detail and quality has not gone unnoticed. From manufacturing and design of an American made product down to the detailed instructions and excellent customer support via phone, email or through website support, AltRider is certainly a contender for quality aftermarket products. The devil is in the details and this product incorporates details. The lower bars are larger in diameter and stronger than most of their competitors. The cage is mounted with thru-hole fittings that are firmly rooted into the bike's frame and interconnected through the tie bar allowing for impact distribution. Consideration for routine maintenance provides access to filters, drains and the battery. The smallest of details like including tubes of thread locker to prevent failures, and laterality indicator stickers are further evidence of a quality product. Considering the cost of repairs, this crash bar system is an inexpensive insurance policy. After testing the crash bars and experiencing the quality that went into the design and materials, it is clear that AltRider builds protection which allows for one to Venture On in confidence.

Leave a Reply