Good Photos by Drew Ruiz

It has been a little while since we told you about our 2017 Honda CRF450RX but this is because we have been testing it more than talking about it. Well, talking about it we have been doing that. Writing about it, not so much. So here is where we are.

One big thing that DBT has been very involved with is land use issues. Through a movement called Rider’s Unite and with the collaboration of ShareTrails.org, Dirt Bike Test is helping to build the ultimate off-road bike and keep trails open. Now how this works in conjunction with the CRF long term bike is kind of simple. We’ve been using our long term bike as a test bed to finally fit all the products onto a brand new CRF450RX Rider’s Unite will raffle off later this year to raise money to not only keep riding areas open but to also fight for more riding opportunity. We will have links and keep you up to date on how you can get involved. Start here: https://sharetrails.org/ridersunite/  When we last left off (UPDATE #1) overall we were very happy with the bike aside from a couple of things. It stalls just a little too much. Even with a much improved clutch for a CRF450, the motocross gearing plus a lightweight flywheel and crank motor character can have the engine stopping at just the wrong times. Our next challenge was to get the bike to have a little more forgiving chassis in rough and rutted off-road conditions. The other thing time on the bike has had us asking is; can we get a little less sting or sharpness–passed through mostly the handlebars–out of it? By trying a lot of things and talking to a few racers we found a couple of little tricks that really helped out.

When we last left off (UPDATE #1) overall we were very happy with the bike aside from a couple of things. It stalls just a little too much. Even with a much improved clutch for a CRF450, the motocross gearing plus a lightweight flywheel and crank motor character can have the engine stopping at just the wrong times. Our next challenge was to get the bike to have a little more forgiving chassis in rough and rutted off-road conditions. The other thing time on the bike has had us asking is; can we get a little less sting or sharpness–passed through mostly the handlebars–out of it? By trying a lot of things and talking to a few racers we found a couple of little tricks that really helped out. For riding in a lot of our areas a spark arrestor is required and the Pro Circuit Ti6 Stainless system has been up to the task. And it has even played into our chassis tuning as well. Since everything affects everything else, we have to say that the power delivery changes are a bonus. The PC system actually settles the bike down to make the stock (#1) just a bit more mellow on the bottom which is good. It makes map #3 even more suitable for times where more aggression and better pick-up is needed. On both maps the top end is spread out and more useable with better pulling all the way to the rev cut. Through the meat of the power it feels like there is more torque. But our big chassis tuning trick was to leave out the lower two exhaust mount bolts. This lets the rear subframe flex a little more and we felt it helped the bike stay down (laid over or not stand up) in the turns with ruts in them. We’re not sure why but a couple of riders noticed it. The mufflers do not care either as the well-built construction has not suffered at all. Even after over 30-hours everything looks tight and like new. Bonus on the PC system is a slight sound reduction and a lot less of a raspy note to the rider compared stock.

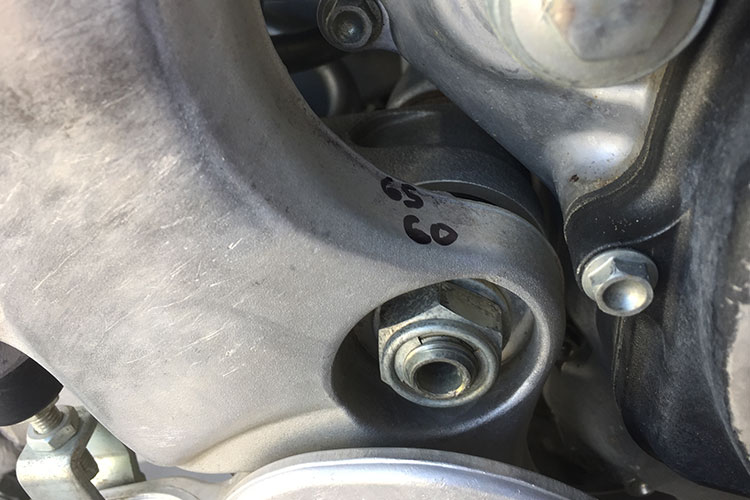

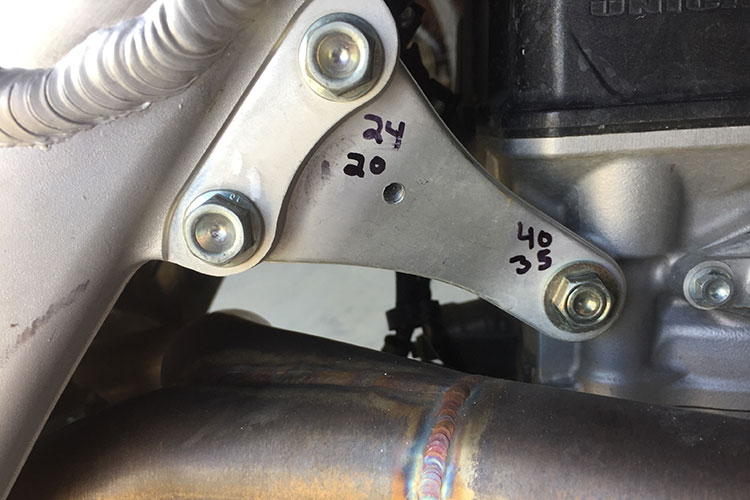

For riding in a lot of our areas a spark arrestor is required and the Pro Circuit Ti6 Stainless system has been up to the task. And it has even played into our chassis tuning as well. Since everything affects everything else, we have to say that the power delivery changes are a bonus. The PC system actually settles the bike down to make the stock (#1) just a bit more mellow on the bottom which is good. It makes map #3 even more suitable for times where more aggression and better pick-up is needed. On both maps the top end is spread out and more useable with better pulling all the way to the rev cut. Through the meat of the power it feels like there is more torque. But our big chassis tuning trick was to leave out the lower two exhaust mount bolts. This lets the rear subframe flex a little more and we felt it helped the bike stay down (laid over or not stand up) in the turns with ruts in them. We’re not sure why but a couple of riders noticed it. The mufflers do not care either as the well-built construction has not suffered at all. Even after over 30-hours everything looks tight and like new. Bonus on the PC system is a slight sound reduction and a lot less of a raspy note to the rider compared stock. Continuing on with the chassis we found that reducing the torque on a few key bolts the bike’s bump compliance and feel in the turns improved even further. The swingarm pivot and upper engine mounts were reduced by about 10%. This was a tip we learned from JCR Honda from testing they did with their GNCC race bike. Another was to drill a 5mm hole in the upper engine mount. It takes some of that sting from a stiff chassis and makes the suspension feel a little more supple even though we were not changing the suspension one bit during this testing. We wanted to test these things before we changed much else so we wouldn’t be masking one thing with something else. And after getting it all dialed we changed everything back to stock and it does make a difference. We tried loosening or removing some other bolts (battery box, gas tank mounts, front engine mounts) but did not notice an improvement or felt some other issued like increased vibration. Best thing, these modifications are all free.

Continuing on with the chassis we found that reducing the torque on a few key bolts the bike’s bump compliance and feel in the turns improved even further. The swingarm pivot and upper engine mounts were reduced by about 10%. This was a tip we learned from JCR Honda from testing they did with their GNCC race bike. Another was to drill a 5mm hole in the upper engine mount. It takes some of that sting from a stiff chassis and makes the suspension feel a little more supple even though we were not changing the suspension one bit during this testing. We wanted to test these things before we changed much else so we wouldn’t be masking one thing with something else. And after getting it all dialed we changed everything back to stock and it does make a difference. We tried loosening or removing some other bolts (battery box, gas tank mounts, front engine mounts) but did not notice an improvement or felt some other issued like increased vibration. Best thing, these modifications are all free. After that we were able to do some additional tuning on the suspension and now we were getting picky and personal. Out back we were mostly standard with a little less high-speed compression to let the bike ride a little lower when moving and tone down the choppy bumps. Up front we are running a little less compression that lets the front settle and be softer in the small bumps without getting harsh. We also added oil, almost 10cc to both legs to give better bottoming feel after running softer compression. We have gone through a few fork seals as well, And after about 50 total hours on the bike we had the suspension serviced, which may have been just a little too long based on the dirty oil that came out. In doing so we also noted that we should replace the bushings on the cartridge as well but did not have the parts when the forks were apart. We cleaned off the debris and made a note for next time. The low speed compression adjustments are very sensitive on this bike and it really pays off to play with them for each rider. We may look to Pro Circuit for a custom revalve when it is time for our next service.

After that we were able to do some additional tuning on the suspension and now we were getting picky and personal. Out back we were mostly standard with a little less high-speed compression to let the bike ride a little lower when moving and tone down the choppy bumps. Up front we are running a little less compression that lets the front settle and be softer in the small bumps without getting harsh. We also added oil, almost 10cc to both legs to give better bottoming feel after running softer compression. We have gone through a few fork seals as well, And after about 50 total hours on the bike we had the suspension serviced, which may have been just a little too long based on the dirty oil that came out. In doing so we also noted that we should replace the bushings on the cartridge as well but did not have the parts when the forks were apart. We cleaned off the debris and made a note for next time. The low speed compression adjustments are very sensitive on this bike and it really pays off to play with them for each rider. We may look to Pro Circuit for a custom revalve when it is time for our next service. Now that our bike was dialed in from a handling and suspension perspective we turned to looking for some additional comfort. The easiest thing to do was to put a set of Fasst Flexx bars on the bike as they will mask a lot of the sharp and stiff feeling on the bike. (plus I really like them for my less than robust wrists.) They did that right away and even allowed us to try a little stiffer fork clicker setting. We ended up going back softer fork setting as it allowed the bike to turn better especially in the choppy bumps. We chose Emig clamp-on grips as we really like the long-lasting yet grippy compound with a smaller diameter, not to mention the simple installation.

Now that our bike was dialed in from a handling and suspension perspective we turned to looking for some additional comfort. The easiest thing to do was to put a set of Fasst Flexx bars on the bike as they will mask a lot of the sharp and stiff feeling on the bike. (plus I really like them for my less than robust wrists.) They did that right away and even allowed us to try a little stiffer fork clicker setting. We ended up going back softer fork setting as it allowed the bike to turn better especially in the choppy bumps. We chose Emig clamp-on grips as we really like the long-lasting yet grippy compound with a smaller diameter, not to mention the simple installation. In changing the bars we also needed to change the bar mounts from the stock ¾-inch to oversized.

In changing the bars we also needed to change the bar mounts from the stock ¾-inch to oversized.

Since we have not met an off-road bike that didn’t love a steering damper we chose to go with the Scotts Steering Stabilizer and mount kit. We ran the under bar mount as opposed to the sub-mount because we wanted only minimum amount of bar rise. In the end it was about ¾-inch taller and we would not want it any more, especially for slower racing types and our mostly average sized test riders.

Since we have not met an off-road bike that didn’t love a steering damper we chose to go with the Scotts Steering Stabilizer and mount kit. We ran the under bar mount as opposed to the sub-mount because we wanted only minimum amount of bar rise. In the end it was about ¾-inch taller and we would not want it any more, especially for slower racing types and our mostly average sized test riders.

Once on the bike every one of our test riders raved about how much more stable and how huge of an improvement the Scotts damper was on the CRF. This on a bike that everyone felt did not need a stabilizer in the first place. It lets you charge into loose rocks, jump into ruts, land crooked in sand and the bike does nothing funny. Through the adjustments we were also ran very light low-speed damping with just a bit higher amount of high-speed damping in the Scott’s so you didn’t even notice it until you really felt it do work. And by do work we mean you expected the bike’s handlebar to kick, jerk or try and turn but instead it would just stay straight. When we had the damper on the CRF and were riding it alongside other bikes without a damper it was really noticeable to a level we have seemed to forget about.

We also can not say enough about how much we are liking the Rekluse Radius X clutch. It is a newer setup from Rekluse that is actually continuing to improve with slight updates from ongoing testing. We have tried a few different settings in clutch pack thickness and its performance gets better and better. There is one funny thing about the Relkuse–when someone pulls in the clutch, bike not running, it feels like you have semi-truck valve springs installed in the clutch, the lever pull is very stiff. But you really never need to touch the clutch when riding unless you want a boost of power that the throttle alone will not give you. And that is rare. The engagement setting is a little chattery if you are going slow and that is one of the things Rekluse is working on for those that might like to do more trail riding on the CRF RX. But the way it engages when you hit the throttle and basically eliminates any stalling issues it is a winning product for this bike. We also added an adjustable clutch lever to position the engagement point to perfection. Now you can still use the clutch like normal if you feel the need. But you still can’t stall the bike even if you try. We got so confident in the clutch that we actually chose to drop a tooth on the rear sprocket to get a little more spread out of the gears no longer having to worry about the tall nature of the first gear and stalling. Plus it gave us just a little more legs in fifth.

We also can not say enough about how much we are liking the Rekluse Radius X clutch. It is a newer setup from Rekluse that is actually continuing to improve with slight updates from ongoing testing. We have tried a few different settings in clutch pack thickness and its performance gets better and better. There is one funny thing about the Relkuse–when someone pulls in the clutch, bike not running, it feels like you have semi-truck valve springs installed in the clutch, the lever pull is very stiff. But you really never need to touch the clutch when riding unless you want a boost of power that the throttle alone will not give you. And that is rare. The engagement setting is a little chattery if you are going slow and that is one of the things Rekluse is working on for those that might like to do more trail riding on the CRF RX. But the way it engages when you hit the throttle and basically eliminates any stalling issues it is a winning product for this bike. We also added an adjustable clutch lever to position the engagement point to perfection. Now you can still use the clutch like normal if you feel the need. But you still can’t stall the bike even if you try. We got so confident in the clutch that we actually chose to drop a tooth on the rear sprocket to get a little more spread out of the gears no longer having to worry about the tall nature of the first gear and stalling. Plus it gave us just a little more legs in fifth. As our stock O-ring chain and rear sprocket were shot (the chain stretched out but mostly side-to-side play that had the chain hitting the frame) so we looked to Delany Drive Components to outfit the bike with a long-lasting setup that we would not have to think about for the rest of the year. The DDC sprocket is a strong stainless steel design with a light swiss cheese cutout so it is still very feathery for a steel sprocket. And in our use these sprockets basically last forever in our desert and typically drier conditions. We paired the sprocket with a RK O-Ring chain and have adjusted it once since instal.

As our stock O-ring chain and rear sprocket were shot (the chain stretched out but mostly side-to-side play that had the chain hitting the frame) so we looked to Delany Drive Components to outfit the bike with a long-lasting setup that we would not have to think about for the rest of the year. The DDC sprocket is a strong stainless steel design with a light swiss cheese cutout so it is still very feathery for a steel sprocket. And in our use these sprockets basically last forever in our desert and typically drier conditions. We paired the sprocket with a RK O-Ring chain and have adjusted it once since instal.

To drop a few pounds we simply added a Shorai LFX14L2 battery and have not looked back. Weight savings up high in the chassis is always welcomed and not needing to worry about having a good strong run at the starter is also a bonus.

Finally for tires we have been running Kenda Parker DT tires for our conditions. They are one of our favorite tires for insane braking grip, especially the front when run in the hard direction. As for grip they are every bit as good as the stock Dunlop AT81s and slightly more durable. For a six-ply tire they do not have any adverse affects on the handling or stiffness of the bike, in fact they seemed to help a little. We run them at 12 PSI and have not had any issues with flats even in rocky conditions.

In the maintenance department the bike has been as simple as can be with a few caveats. Sure we miss a simple no-tools design for air filter access but pulling the seat is only a little effort. Then you must be cautious with very dirty filters due to the downward opening of the air boot. You can look at the tops of the intake valves with the throttle body open and dirt will fall right in there if you are not careful. Oil changes are basic but we have not mastered opening the huge oil drain plug without getting oil all over our hands yet. We have not bothered to check the valves as the bike starts instantly and we have not sucked dirt or have any reason to believe they would be out of spec. We should just to know where they are, maybe in a few more hours when we quit riding it so much. So far we are really happy with the CRF450RX but with one very important point. This is not a trail bike. We have taken it on some trail rides in slower and technical terrain. Every time we wished we were on a different bike more suited to trail riding. It is just 10% removed from being a full-on motocross bike and we have never enjoyed trail riding motocrossers. It is outside the design parameters of this bike so we don’t criticize it for this trait. We mention it just to be clear about how we really think the bike should be used.

So far we are really happy with the CRF450RX but with one very important point. This is not a trail bike. We have taken it on some trail rides in slower and technical terrain. Every time we wished we were on a different bike more suited to trail riding. It is just 10% removed from being a full-on motocross bike and we have never enjoyed trail riding motocrossers. It is outside the design parameters of this bike so we don’t criticize it for this trait. We mention it just to be clear about how we really think the bike should be used.

So when you are riding faster terrain, jumpy terrain, hitting a natural terrain GP track or even out hill climbing this bike is basically magical. It has all the power you’d ever need in a very rideable package that loved to be pushed hard. The handling is precise and with some of our small adjustments now the chassis is a lot more calm and even more planted. It is a racer at heart and will do a good hour long session on the stock tank for most riders and conditions. We’re not finished yet and will be looking at some gas tank options and seeing about chain wear pads and guides pretty quick. And we’ll make it look a lot flashier when it needs a polish. We are keeping an eye out on this all-new engine’s durability and looking forward to a lot more miles of fast hard charging fun on the 2017 Honda CRF450RX.

So when you are riding faster terrain, jumpy terrain, hitting a natural terrain GP track or even out hill climbing this bike is basically magical. It has all the power you’d ever need in a very rideable package that loved to be pushed hard. The handling is precise and with some of our small adjustments now the chassis is a lot more calm and even more planted. It is a racer at heart and will do a good hour long session on the stock tank for most riders and conditions. We’re not finished yet and will be looking at some gas tank options and seeing about chain wear pads and guides pretty quick. And we’ll make it look a lot flashier when it needs a polish. We are keeping an eye out on this all-new engine’s durability and looking forward to a lot more miles of fast hard charging fun on the 2017 Honda CRF450RX.

Support DBT by shopping through the links below:

5 Responses to “Long Term Update #2: 2017 Honda CRF450RX”

Jimmy Lewis

Rick,

Thanks for getting back to us on this. We ride in some “east” type conditions but they are typically not as wet so it is awesome to get feedback. Even if it isn’t all positive. All this testing takes time and commitment, something most of the “bolt it on and make it better for me” media does not do. Now we are going to some other known ways of getting less chassis feedback (mousse, Flexx Bars) and the bike still cuts like a knife on the ground without making the rider pay.

Jimmy Lewis

Matt,

I’d seen this but I’d have to try it out. With all of our effort to reduce the chassis stiffness anything that would or could tie up the flex could really hurt handling. Works Connection tries to isolate this with flexible mounting but again, would need to be tested.

Matt Bennett

Its just something you put in the drain when when draining the oil. It wouldnt effect the flex or handling at all. You just lay the bike on its side, unscrew the plug, screw this device in and close the tube, sit it back up, open the tube. When its done draining, unscrew it and put the stock plug back in….

Jimmy Lewis

I need to look closer at the part. Sorry, thought it was a skid plate…

Paul Bradshaw

I’m having a lot of these same stiff feeling problems. So far, I’ve added stiffer springs (.53F, 6.3R for 230lbs), went way out on compression and a little on rebound, added Twisted Engineering 3X flex bars, and removed the exhaust bolts. It’s not enough in the New England woods. I can barely hold on to the bars at a race pace, and my front end deflects easily when its wet out. I’m thinking a revalve is in order, and maybe try the hole in the engine hangars. I can’t see a 5mm hole doing much though.