Hinson Inner Hub, Pressure Plate and Fibers, Steels and Springs Kit for Honda CRF450R

Company: Hinson

Price: $499.99

Additional Pricing

- $199.99

- Improved clutch feel and response.

- You can build a larger and more versatile burst of power to get over and through certain obstacles.

- Harder Parts = More Durability.

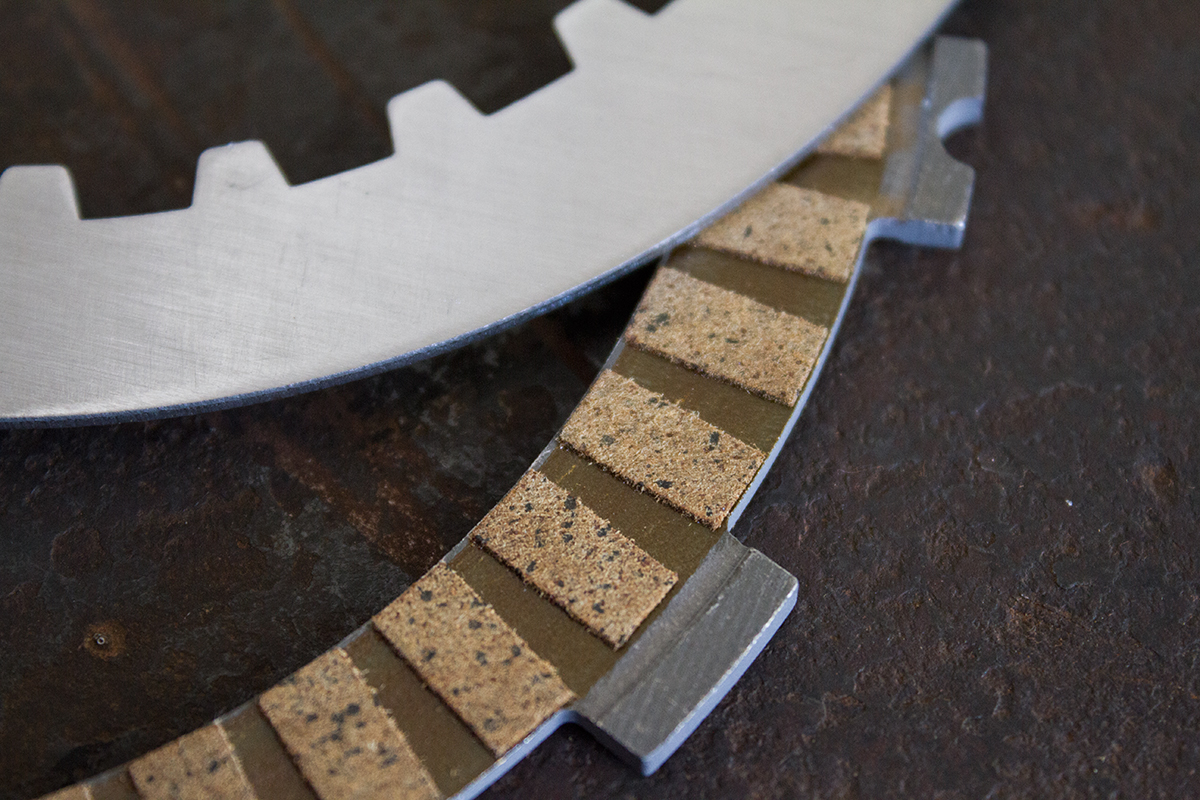

- Use of Kevlar and carbon fiber clutch plates can cause excessive wear on hard parts.

- On the pricey side!

What it is

- An aftermarket solution to clutch drag.

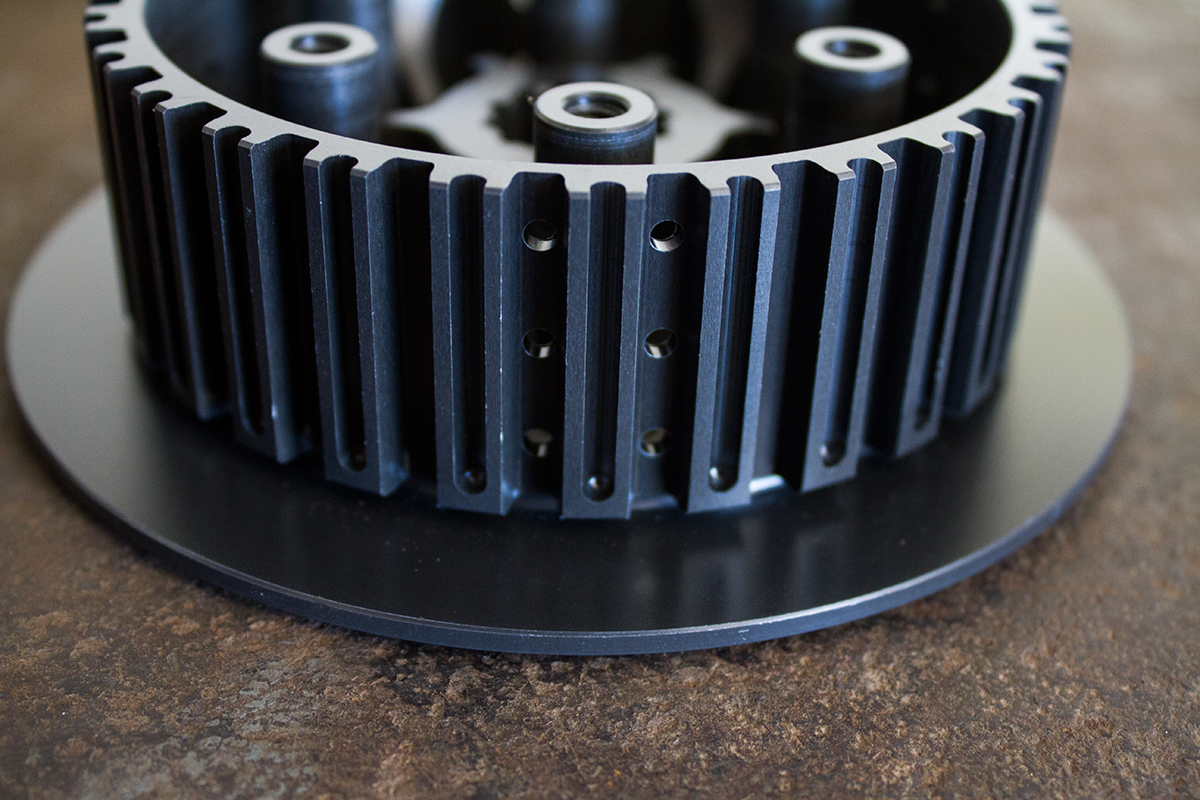

The Hinson Clutch Components Inner Hub and Pressure Plate is a performance upgrade combo package built to mirror stock Honda components that you have to purchase as a kit. It mounts up to the stock basket’s of the 2013 to 2016 Honda CRF 450R’s. Hinson claims this product is a modification as well as a far more durable option than replacing your stock inner hub and pressure plate with another stock one. The FSC Kit (Fibers, Steels, & Springs) which is considered a wear part is claimed by Hinson to be an upgrade from OEM.

How it works

- Harder Material and stiffer springs give the clutch pull a different engagement/ disengagement point.

Installation is the first step. You will want to lay the bike over clutch cover side up. I wedge a screwdriver in the hollow swing arm bolt while I have the brake pedal pushed down to hold it out of the way. Now you will have access to pull the cover off and remove the stock inner hub pressure plate and clutch fibers and steel plates. All that will be left is the stock clutch basket. This is a relatively easy upgrade to be done if you have an impact driver to help release the nut holding the inner basket. Install the locking crush washer and torque the main shaft nut to 59 foot pounds of torque this is called for from 2013 through 2016. From experience this is made easier with Hinson's adjustable clutch holder tool that slides into the inner hub groves. Now you would want to install the FSC kit.

The Hinson Clutch plates are claimed to offer more bite for better control when you want to slip the clutch or build a burst of power. The springs are made from high temp steel developed specifically for this motor to give no more or less clamping pressure than what is called for. Don’t forget to pre-soak your fiber plates in oil. Make sure that your stock jutter spring and seat spring are removed which are a flat type of spring that will be found on the bottom of your clutch plate stack. The plates will install in a specific order. Starting and ending the stack with a fiber that is marked black you will alternate through 8 fibers and 7 steels. Keeping the steels with the sharp edge up. Now you can install the pressure plate. Lining the marks up is the only way it will properly install you’ll need to look for the etchings. Finish it off by evenly snugging the bolts with your new springs and torquing them to 9 foot pounds which is called for from 2013 to 2016. There should be only the slightest bit of play if installed properly. The last step is an important one and Hinson recommends petroleum based non-synthetic 80 weight transmission oil that should be changed before each ride for riders hard on the clutch. This will result in the best performance and clutch life.

Right after install I had learned that my clutch levers point of engagement had shortened when adjusted properly. This was much shorter of a pull compared to the stock inner hub and pressure plate which dragged when I went to release the clutch. This resulting in a bit of over rev instead of a built up burst of extra power like I now felt. This common feel in the CRF clutch is the caused by the OEM material being too soft which results in slippage and power loss through the clutch. Clutch slipping also causes motor heat which can happen in a period of just 20 minutes. Clutch slipping creates power loss and unwanted wear transferred through your engine.

I found the upgraded hard parts became a gain of performance as well as a boost in durability. There wasn’t an addition of horsepower or torque, it was an addition of control of those two tools being properly delivered to the rear wheel. I found myself able to hug tighter to the inside of turns for the shortest route before jumps because I was able to build a larger and far more controlled burst of power to get over more things in a shorter distance than with the stock components.

The clutch also helped me when it came to the most important part of the race… the start. I was able to mix the clutch and throttle at a lower rpm to leave the gate with the least amount of wheel spin. This was because the clutch didn’t slip its way out under the load it had, it disengaged as I told it to and slipped when I told it to at the lower rpms I wanted. During a thirty minute high-intensity moto while abusing the clutch I only rolled out the adjuster tightening the cable a handful of times--less than before. An average rider may not ride hard enough to experience that situation, but sloppy clutch use can also aggravate the feel at the lever. The reason this clutch allows you to abuse it more can be attributed to the high grade aircraft aluminum and akadize coating the components are treated with. I can’t guarantee how long the Hinson Clutch Components inner hub and pressure plate will last, but from my experience with Hinson products I have had the hard parts last for upwards of two to three years on bikes that get ridden hard. I usually switch out my clutch plates every 15 to 30 hours.

This inner hub and pressure plate for our 2016 CRF 450R cost $499.99 and stock cost is $157 and some change. For me it is not if you’ll need to upgrade your CRF’s clutch, but when you have to do it. When you do want to upgrade and not a replace I can recommend this fix. Especially if you like to use your clutch as much as I do.

Help support this site by purchasing through this link:

Leave a Reply