Jay Clark’s 1996 CR250 Resto

Story and Photos by Trevor Hunter

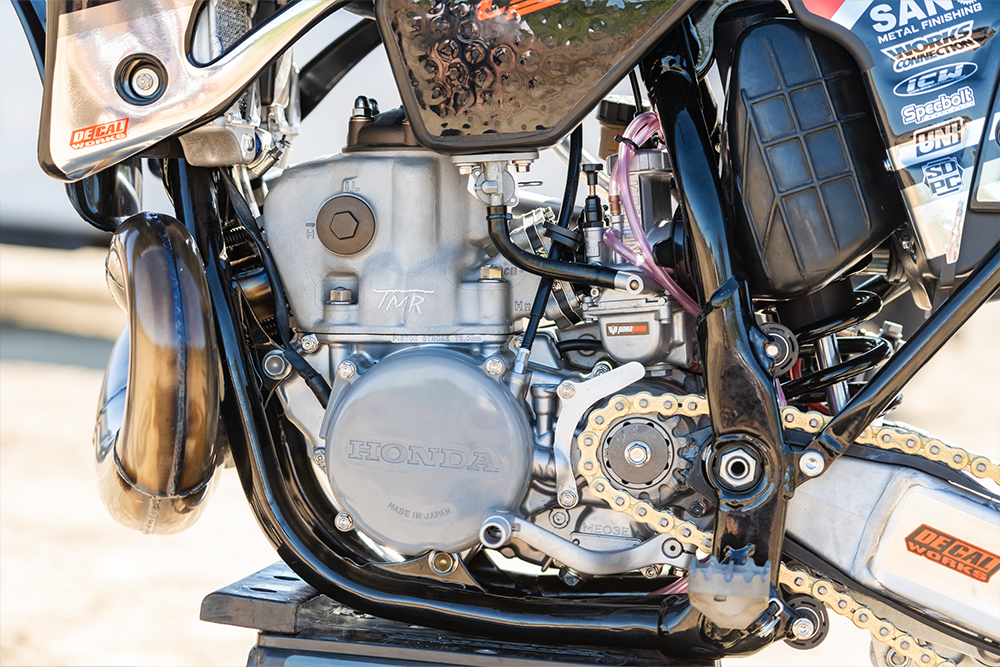

Its safe to say nobody in the industry builds as many bikes as Jay Clark does each year — not to mention the variety of bikes that come to life in his garage. From old-school two-strokes, to the most tricked out modern four-stroke you can build, Jay builds it all. He recently brought out this stunner of a bike, a 1996 Honda CR250, to take some photos of, drool over, and hear it sing as he warmed it up on the stand. Unfortuntely, we couldn’t do what we do best and swing a leg over it, but we were able to walk away with a little info on this bike in particular and get some tips and tricks from the pro’s pro himself on restoring older bikes where parts may be discontinued and scarce.

What are the hardest parts to fix/track down on vintage bike builds?

When you are dealing with nearly 30 year old bikes there are many challenges when trying to make a bike as good as it once was and Jay feels that these 1995/96 bikes were not really made to be ridden hard for 30 years. Many parts wear out and we will discuss those.

Engines — Transmissions are important and the problem is that there are basically no OEM quality replacement pieces that are commonly worn out available for these older bikes. Searching online for used is about the only solution and that is a risk of finding pieces that are not much, if any, better than what you have. Jay said it took eight lower ends to make the five complete.

Engine Center Cases – Cases are often damaged beyond repair. This is usually from piston or crank failures (guys running their Honda into the ground until it breaks). When it does break, it can be catastrophic. Drain bolts and chain guide areas can also be damaged. Jay was able to get a repair and weld up nearly every case, with three thrown into the recycle bin in the end. Of course you can’t buy new OEM cases still.

Cylinders — These cylinders have long been unavailable from Honda. Jay does prefer to use the stock cylinder replated by Millennium rather than a sleeve. Jay had 3-4 extra sleeved or otherwise unusable cylinders left over.

Crankshaft— There are some after market full cranks available. Jay prefers to find good usable cores and rebuild the cranks with the ProX rod kit that is as close to OEM as you can get from Japan. We’ve tested ProX rods recently and have seen excellent durability out of them, matching OEM lifespan on bikes that are ridden hard.

Suspension — This is an area that is commonly overlooked by the beginner project bike builder. Many older bikes did not have fresh oil changes regularly and thus the components can be worn out, not salvageable, or in need of hard anodize. In Jay’s case, he needed both. It took ten sets of used suspension to make the finished five sets that Race Tech completed with all needing Hard Anodize to repair the internal diameters. Many shock shafts are ruined as well.

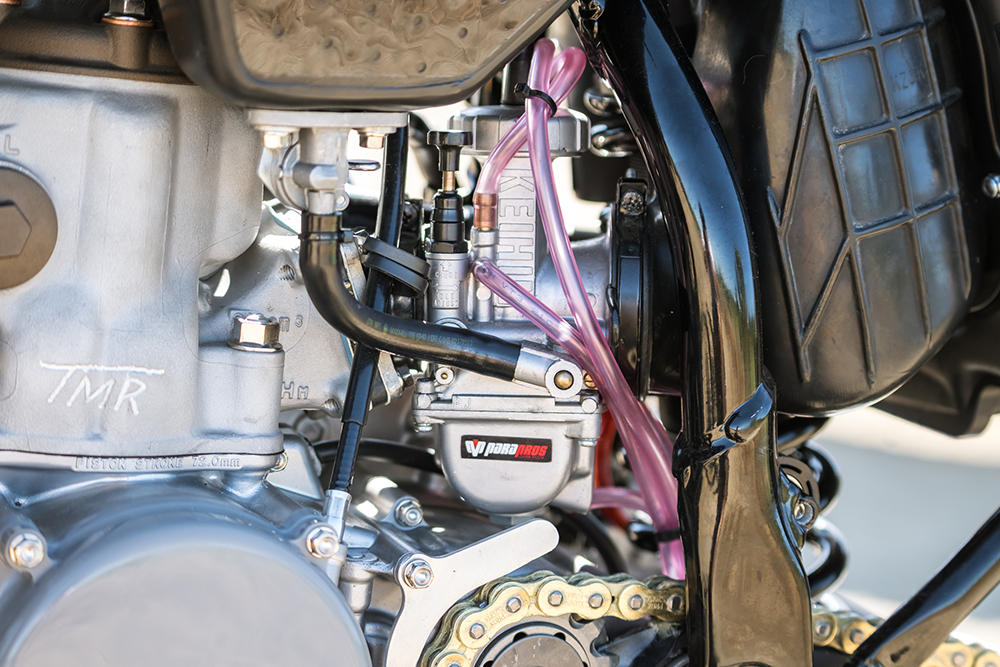

Air Boots from the air box to the carb are not available and these have proven hard to find for a reasonable price. Jay bought his last two in good shape for the bikes off of ebay. The intake boot from the reeds to the carb are long unavailable and Jay was in good shape to salvage the stock ones with the V-Force reed cage. If you can’t find one, you could run a Boyesen reed cage and get the intake included.

Kick Starter levers are no longer available and nearly every one is so clapped out it will rattle on the pipe. Ebay does have new ones listed in the $60 range that work well and of the six jay bought, only one of them didn’t line up correctly. Radiators are hard to find in good shape and most aftermarket do not fit well. Jay likes to use the stock rads straightened up by ICW.

What parts are commonly difficult to obtain when rebuilding older bikes like this?

Rubber parts, cases, and suspension — all listed above.

What parts or aspects of the bike do you recommend everyone replaces or carefully inspects when rebuilding an order bike?

All Bearings and seals should be replaced on the engine, suspension and chassis. Swing arm, linkage and steering bearings will almost certainly all need attention.

When rebuilding older bikes, what do you feel is the most important to change or modify (ie. Suspension, motor, ergos, etc)

Jay feels keeping it simple is most important on these older builds. Jay preaches that no matter what you do to the engine or suspension, it will not be “as good” as current bike. Keep it as simple and cheap as you can since you will not be lining up to race A1 with these bikes. And as we just proved with our Big Bear Run Torture Test, the rider makes way more of a difference than a bike ever will.

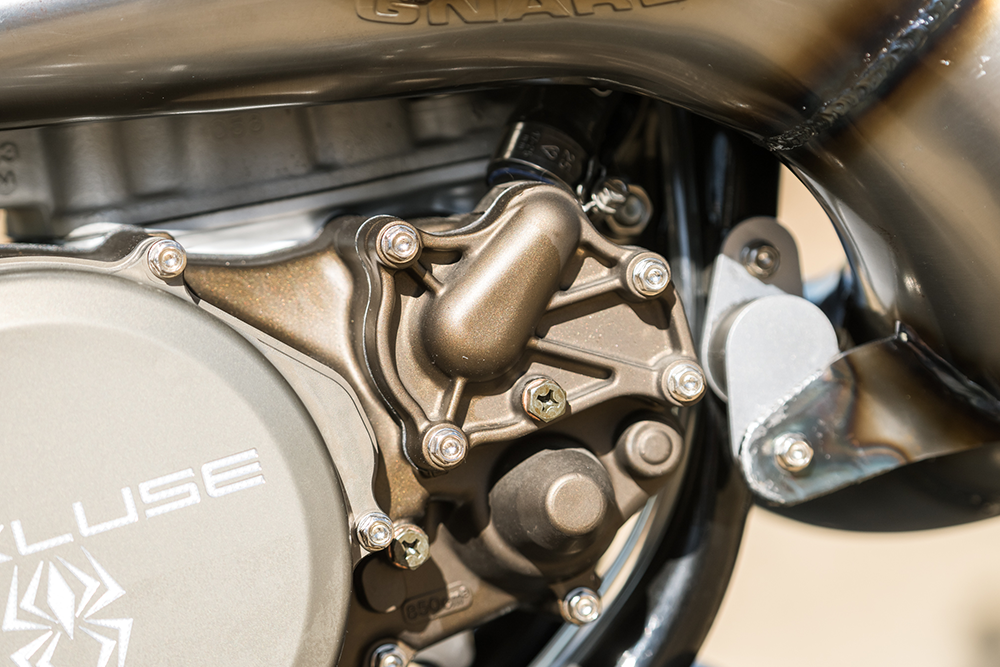

Since Jay has along time relationship with TMR -Tom Morgan he insisted him to help set up each cylinder/head. Surprisingly, most of the stock electronics are really durable with the stock coil, stator and CDI all being utilized after vapor honing.

Of all the older builds you’ve done, what bikes were the easiest to build and get parts for and what were some of the hardest?

Jay thinks that the Yamaha bikes as a whole tend to be a bit easier to find OEM parts for.