Photos By Trevor Hunter and Eric Hallgath

After our last update on Yamaha’s YZ250FX, we decided to tear down the motor to inspect the wear and perform some preventative maintenance on the machine. The bike had a total of 64 hard, mostly racing, hours on it at the time of the tear down with only the standard Maxima Pro Plus+ 10w-40 oil changes with an OEM oil filter every 5-6 hours with the exception of the 24 hour race last year. Being my first four-stroke rebuild, I underestimated the amount of work needed to remove the motor from the frame. With a plethora of wires and electronics going in every direction, it was a bit overwhelming compared to my usual YZ125 that I have done several times before. Now I understand why some riders are stuck on the simplicity of the two-stroke and I’m not even to the cams and valves yet!

After finally getting the motor out, we took it to John Braasch of Braasch Motorsports. He was a long time Team Green mechanic for countless years before going off on his own. He will work on just about anything you throw at him and you will always know it was done the right way when he works on it. He also assisted our 24 Hour Sr. Team in getting the Beta 430 RR-S ready for the grueling race last October. But I didn’t just drop it off, I stuck around to learn about what makes the four-stroke go. It was more time consuming than tearing down a two stroke, obviously, and there are a lot more things you must pay attention to like the cams and valves. However, it wasn’t as overwhelming as I thought it would be as I watched/helped John tear apart the motor and it was less difficult than I imagined. Next time, with some guidance, I feel confident in being able to piece everything together in working order. I’ll need a few special tools but those are investments.

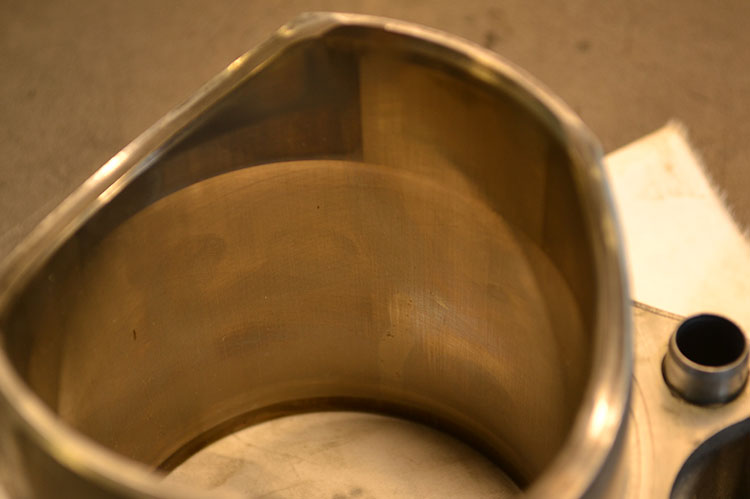

After tearing everything apart, the inside of the motor looked great. We aren’t surprised after doing the same with our 2015 YZ250FX a couple years ago. All the valves were still in spec with the L/S Intake at .15mm, R/S Intake at .13mm, and both the R/S and L/S Exhaust at .17mm. Additionally, the piston still looked like it could be used some more though we wouldn’t recommend it with that many hours and the engine being apart already. We wanted to have a fresh bike for upcoming races and be preventative to help avoid DNFs and even more costly repairs should something be out of spec. Racing four-strokes are often overlooked and those are the failures you often hear about.

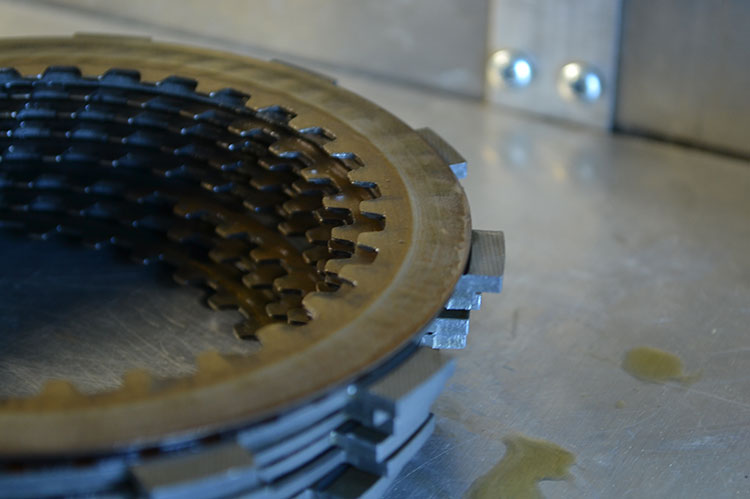

We replaced all the seals and gaskets, the clutch nut lock washer, the main bearings, and the piston assembly only because we had it apart, not because it was needed. Braasch, from his do it like a factory mechanic attitude, wanted to replace almost everything. That is standard operating procedure for high level racing motors. But in his opinion after seeing the Yamaha all apart, there was no real reason to tear the bike apart due to wear other than the standard piston. But, since you can’t really see inside the motor, we thought it would better to check then find out the hard way. Preventative maintenance is key and now we are even more confident in the Yamaha 250 four-stroke after this teardown.

We have also continued to test the Pro Circuit suspension and have made drastic improvements with it. Gone are the days of bottoming out on almost every bump we encountered. Also here is a link to the Pro Circuit T-6 exhaust system we recently tested. When the bike was put back together, I raced the Prairie Dogs/Desert MC Night Team Scrambles out at Glen Helen Raceway with Chance Fullerton and we were both impressed with how well the suspension worked for both of us–even with a couple pound headlight light mounted to the front of the bike. We actually took the overall win over lots of bigger bikes. You can read about how it worked HERE.

The YZ250FX was also utilized for riding sweep/tearing down the course at this years Last Dog Standing the day following the night race. And per Jimmy’s instructions, it wasn’t taken down or up anything too serious to avoid damaging anything because I certainly would have had I tried. Despite all the stop and go to pick up arrows and ribbon off the trail and riding through the tight trails following other riders, the electric starter still works great with the original battery and we are still on the original clutch at 75 hours. They aren’t showing much signs of wear and we feel it could easily reach 100 hours.

Additionally, we are testing XC Gear’s SPURZ foot pegs and Mako 360 bar mounts on our Yamaha. The SPURZ foot pegs feature interchangeable inserts to provide a more comfortable ride and reduce the vibration. The Mako 360 bar mounts are similar in that rubber elastomers isolate the handlebars from any metal to metal contact with the rest of the motorcycle which is also designed to reduce vibration and provide more comfort. Look for tests soon.

We’ve had another great experience with the 2017 Yamaha YZ250FX. Starting out life thrown into a 24-hour race (and almost winning) then being used primarily as a GP race bike, it didn’t stop us from taking it on trail rides or practicing motocross on it. Since it isn’t changing much for next year the FX is a great platform for all-around use. After looking inside the motor again, Yamaha obviously increased the durability in the area of the small end of the rod, our only concern last time. And aside from suspension that is a little on the soft side for our much faster than normal riders riding higher-speed and more motocross oriented courses, there is little for us to complain about. Other than we don’t get to keep the bike for longer.

3 Responses to “Long Term Update #2: 2017 Yamaha YZ250FX”

George Madaris

Excellent article. Great writing!

Jimmy Lewis

Jake,

Some follow up is going on with this. We know about the DLC coating and Trevor is re-checking with the mechanic to see if he got his facts straight.

Jimmy Lewis

https://dirtbiketest.com/wp-content/uploads/2017/03/PC_250FX_T6SS_H10.jpg

This is a good base map for more open exhaust